For this build, I decided to go with Monsoon Hardline PETG Tubing 1/2" ID, 5/8" OD. I initially had purchased PrimoChill PETG Tubing, but decided that the diameter was too thin and liked the look of ⅝” OD better. This is my first time “tube bending” so I purchased a lot of it since I knew that I had to account for the varoius screw ups that would occur. Luckily it is not very expensive.

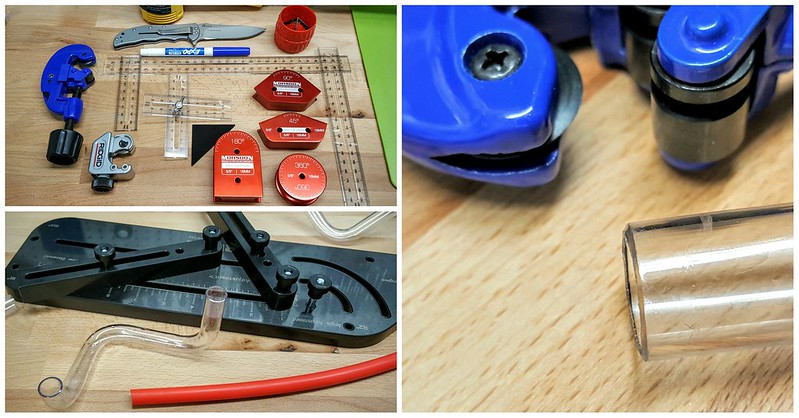

Since it was my first time working with hardline tubing, I had to acquire a few tools to make sure my bends look good. I already had a few things, like the rotary pipe cutters and a heat gun, but also picked up some Monsoon Mandrels to help form bends, a measuring kit, and a tube bending rig made by Barrow which came in really handy.

I have noticed that a lot of people cutting tubing use a hacksaw, but I personally thing the rotary pipe cutter is a much better tool. Not only does is make very straight cuts, but it leaves no mess, and gives the tubing a nice beveled edge as can seen in the picture above, and ensures I don’t damage the o-rings when sliding them on for the fittings.

The Barrows bending rig was very useful when doing more complex / multi angle bends, and assured not only my angles were dead on, but that the tubing was straight throughout the level plane I was working with. It also allowed me to keep things stable when doing larger 180 bends than what the Monsoon mandrel kit supported. Used a can of compressed air as a form for one of the bends, and it come out really nice.

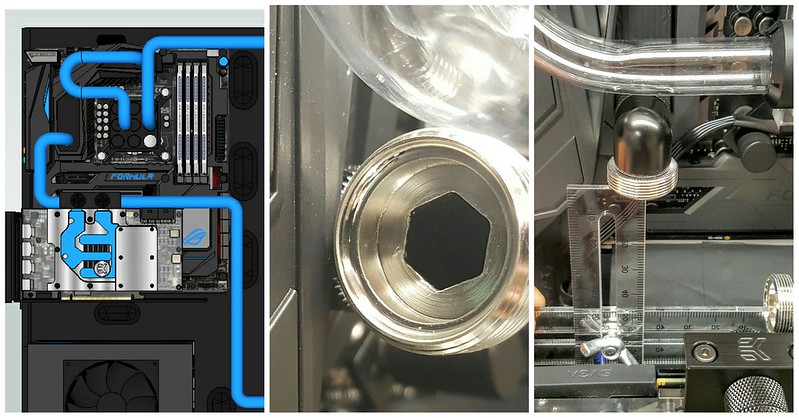

For the most part, my bends held true to my original 3D render which I was glad to see. One place where I had to simplify a bit is where the Motherboard outlet connected to the GPU block. I was initially going to go with a nice multi-bend solution, but realized after installing the fittings that my plan wouldn’t work. There wasn’t enough clearance between the fitting and the motherboard housing to do a 90 degree bend from that location. So I used my measuring kit to form a more simple

“L” bend directly to the GPU block.

Not as fancy, but the end result still looks great. Towards the end of the process, I was getting really good and quick at making quality bends. I may change things around at some point, but for now, I am happy with the end result. Time to move on to finishing up making some power cables and getting them sleeved.

Hey man, I'm really interested on know how did you configured this little screen with the specs of PC, there is a post showing this?

ReplyDeleteMy email is manoelpasinrangel@hotmail.com , if there isn't a post you can send me a little explanation about, please?

Thanks,

Manoel Rangel.

Head over to this page for more info on the System Specs LCD screen:

Deletehttp://mrarmageddon.blogspot.com/2016/06/project-open-core-hardware-system.html

Hey man, I'm really interested on know how did you configured this little screen with the specs of PC, there is a post showing this?

ReplyDeleteMy email is manoelpasinrangel@hotmail.com , if there isn't a post you can send me a little explanation about, please?

Thanks,

Manoel Rangel.

It seems that fittings for 1/2" ID, 5/8" OD tube is very rare. Am I missing something? Mostly what I see for 1/2" ID is 3/4" OD fittings.

ReplyDeletehttps://www.amazon.com/Bitspower-Compression-Fitting-Matte-4-pack/dp/B00VHC8FFM/ref=sr_1_4?ie=UTF8&qid=1470760392&sr=8-4&keywords=bitspower+g1%2F4

BitsPower makes fittings for their own size tubing. I used Monsoon fittings which are pretty easy to find, and come in a variety of types and colors.

DeleteHere is an example of the fittings I used (Monsoon G1/4" to 1/2" ID, 5/8" OD Hardline Economy Compression Fittings), but these are Blue

Deletehttps://www.amazon.com/Monsoon-Hardline-Economy-Compression-Fitting/dp/B01C3J06JU/ref=sr_1_2?ie=UTF8&qid=1471752289&sr=8-2&keywords=Monsoon+G1%2F4%22+to+1%2F2%22+ID%2C+5%2F8%22+OD+Hardline+Economy+Compression+Fitting

Here are some other fittngs of the same size, but a bit more "Fancy"

https://www.amazon.com/Monsoon-Center-Hardline-Compression-Fitting/dp/B00M9A5HNE/ref=sr_1_4?ie=UTF8&qid=1471752155&sr=8-4&keywords=monsoon+hardline+fittings