Project Index:

There are many options available to those who want to build a mining rig. You could use a normal PC Case if you only have 2-3 GPUs. Even then the heat and space restraints make traditional cases not a great choice for mining. Some are very simple, consisting of shelving or even milk cartons, modified to hold the required hardware. These will work, but honestly look a bit ghetto. Others are more elaborate cases built specifically for Crypto Mining. These look great, but are a bit expensive coming in around 200-300 dollars. I settled somewhere in the middle, decided to make my own open air case, but add a few aesthetic upgrades so it still looks somewhat nice.

For those that have been on my Project Blog before, you know that I take pride in my

custom PC builds, and that I have a thing for black cases with blue highlights.

Design choices for this system were based upon 3 main requirements:

- Open Air design allowing us to easily configure the hardware in a way that it will provide adequate spacing for airflow, and maintenance when needed. When looking at 6x GPUs in one system, you must take heat into consideration.

- Modular in nature, allowing it to work with a variety of GPUs, Power Supplies, and Mother Boards

- Stackable design to allow for minimum footprint if building multiple systems. I plan on building 2 systems in my home, so had to make sure this was an option as I don’t have a ton of extra space to have multiply systems lying around.

So let us begin with some basic dimensions. There are plenty of DYI sites and forums with people showing their builds, but there is very little consistency between design and sizes. So instead of following someone’s, I designed mine from the ground up. Here are the basic dimensions

Materials

The frame of this case will be built using 3/4in Angled Aluminum from a local hardware store. Its thickness is 3/16th in and they come in lengths of 36in. The various fasteners will be listed below. Also using 3in x 3/4in finished wood planks to serve as the bottom of the case, and the GPU resting plate. Full material list below, came to around $45, including matte black spray paint.

- 3/4in x 3/16in x 36in Angled Aluminum (x5)

- 3/4in x 3in x 96in Sanded Wood Plank (x1)

- #6-32 x 1/2in Machine Screws & Nuts (x12)

- #6 Flat Washers (x12)

- #6 Lock Washers (x12)

- #8 x 1in Flat Phillips Wood Screws (x12)

- #8 Finish Washers (X12)

- Matte Black Spray Paint (x1)

Additional parts that will allow for an easier build, and make things look better.

- PC thumb screws for GPU plates and Motherboard (x12)

- Motherboard Standoffs (x6)

- Plastic Corner Brace for PSU (x2)

- Rubber Feet / Standoffs (x4)

- Illuminated PC Power Button (x1)

After acquiring all of the parts, the first step is to cut your aluminum lengths. From the 5 longer pieces listed above you will need to cut 4x 20in, 4x 16in, and 4x 10in lengths. Measure everything out before cutting and you should have plenty to work with.

Next are the wood plants. Cut 4x 16in, and 1x 20in lengths. You may need to shave a tiny bit more off each cut depending on how you cut. My 10in chop saw was just about perfect cutting right down the middle of the line, allowing the wood to drop in snug but not so tight that it would warp the frame.

With the cuts all made, its time to start assembling the frame. Starting with the front bottom section, hold them together and drill a hole through both pieces of angled aluminum with a 1/8in drill bit. Once the hole is drilled, thread in your screw along with washers and nut to secure the parts together.

Screw [] Flat Washer [] Angled Aluminum [] Angled Aluminum [] Lock Washer [] Nut

With the two bottom front corners are assembled, start on the top front corners. Once you have the front “box” assembled, time to add the wood plants to the outside edges. As before we will line them up and then drill using the 1/8in bit. Then thread the wood screw through the finish washer, and into the aluminum with the wood behind it.

With the two outside planks installed, time to repeat the process and build the back of the frame just was we did with the front. Once that is done, the frame should be pretty solid. Now we add the GPU support brackets. I measured 9cm from the bottom of the case to where the GPU support bracket would be mounted. Attached the 2 supports as shown in the picture below, and then place the 20in wood plant between them, roughly 15cm from the front of the case. With that completed, the frame is assembled, and technically could be used at this point.

From this point on, most of what I am showing is aesthetic in nature or meant to keep things more tidy. Not required, but will make things look better and help with cable management.

Some people chose to secure the GPU plate to the case using Zip Ties. I don’t like the look of that and would prefer to use Thumb Screws to secure them better. I measured out spacing for 6x holes to go on the top front bracket, and used my drill press to punch through, first covering it with some painters tape. Her you can see that I did more than just the required 6x holes to give me a bit of flexibility when placing cards, just in case I have one that needs a bit more space due to heat issues.

Here is an example of how a GPU will sit both on the top frame with the thumbscrew securing it, and the GPU bracket we added to the case, where the PCIe Riser card connects to the GPU

Next I used some plastic Corner Braces to secure the PSU (Power Supply) to the case. One on the side and one in the front was enough to keep it secure, but still easy to remove if needed.

I also drilled a larger hole to be used with a latching Illuminated PC power button. Not necessary, but I prefer to the look and function to this over the jumper cable method. (Note, I did use a wider piece of aluminum for the front side of the case to accommodate the button. If you have a smaller button, this won’t be an issue).

With the case construction completed, on to paint. Although not necessary, I prefer the look of matte black over the scratched up aluminum and bare wood. Easiest way to paint something like this is to hand it from a wire, and spraypaint while suspended.

Give it a light coat making sure to not apply so thick as to have run lines. Allow for appropriate dry time, then apply a second coat. After final drying stage, the case is done!

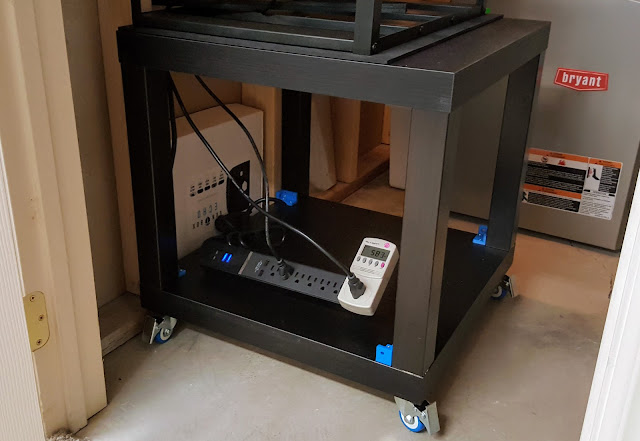

Next post will cover building a stand with rollers/castors, and then on adding the components. As a final “extra” step, I added some carbon fiber vinyl to the GPU mounting bar, to keep the metal GPU plates from scratching off the paint. Here is the final result, ready to accept the hardware!