Project Index

Assembly

Now that all of our wood pieces have been cut out and prepped, its time to start putting this thing together! This part was a bit more tricky than I had anticipated, and took a lot of trial and error to get everything to line up perfectly. The idea is to use small wood "batons" to act as supports and stops for the various panels.

The picture below shows how they are used to block the various panels into place. The key is to stat with one side first, get everything lined up how you want it, and mark your joints. Then mark those same joints on the other side before you start gluing or nailing anything down. I used painters tape to hold everything together while testing out the fit of my markings just to be sure.

After you have marked both sides, and are pleased with the fit, its time to secure everything to the panels. I used a combination of wood glue and brad nails. You can probably get away with just using wood glue, but with an air compressor, putting in a few brad nails for extra support is an easy task.

Once all of the batons were secure and in place, its time to begin putting everything together. Starting with the monitor panel, I worked my way around the cabinet, gluing and clamping down the various pieces as can be seen below. If your measurements are good, everything will fit together neatly. Keep things clamped together for at least a few hours before you move the cabinet. I recommend letting it sit with the clamps on overnight.

Electrical Wiring

With the cabinet assembled and the glue drying, it went ahead and added the modular power inlet. This using a standard computer / monitor power cable, which I then wired directly to a surge protected power strip.

Pretty simple to install, just cut a hole to fit, and after a bit of file work, made sure that it went in nice and snug. Don't screw it in yet, as we need to paint before securing this to the cabinet.

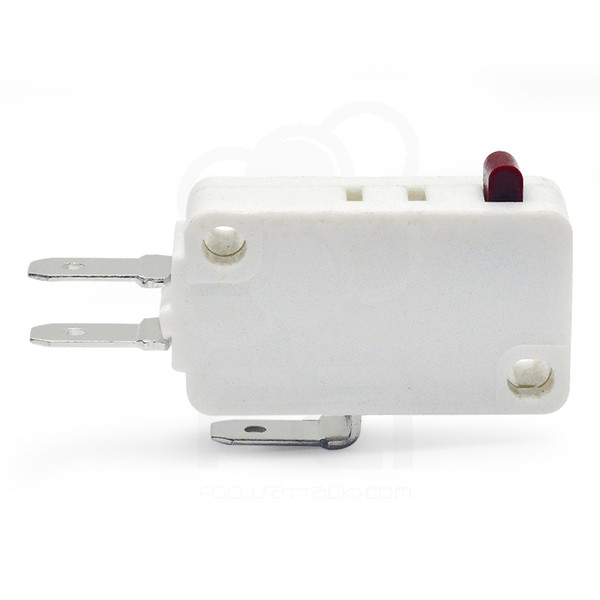

Once I was sure it could be mounted in the hole correctly, I started the wiring process. I removed the wall plug end from the power strip and wired it to the inlet switch as shown below. I chose to use female spade adapters instead of directly soldering the connections. Note that there is more than one way to wire this switch, but the way shown here will allow the switch to light up when turned on.

Painting & T-Molding

With the cabinet fully assembled and the glue dry, its time to paint! I have seen people use cans of spray paint for this part, but this MDF really sucks up the paint, and you will go through a lot of cans of spray paint to cover properly. My wife had recently painted all of our interior doors black using a sprayer, so I used the left over paint and her sprayer to take care of my paint job. Would have done it outside, but the temperature has started to drop, so did it in the insulated garage, with some plastic protection applied.

I gave the paint a solid 24 hours to dry before I moved the cabinet from the garage, back down to my project room. With everything coated in a nice black finish, next step is to add the T-Molding. I am using 3/4in T-molding to match the width of the side panels. Using a rubber mallet, I slowly worked my way around both sides. When getting to a corner, I nipped a bit of the insert to make it easier to get flush corner bends as shown below.

Here we have a picture of everything painted black, and the T-Molding installed. If you have seen any of my other projects, you will know that I am a bit fan of Black/Blue themes. It looks great with the T-Molding installed against the black paint. The T-Molding also served as protection for the edges of the MDF, and adds a bit of grip to the bottom keeping the cabinet from sliding around.

With most of the exterior work completed, next step is to install the display. This was tricky due to the built in speakers this monitor has. I'm not planning on using the built-in speakers but they increase the length of the monitor enough that I couldn't mount it without conflicting with the controller board buttons.

The solution was to flip/rotate the display 180 degrees as shown below. I used the existing VESA holes on the back of the LCD to mount a piece of pine to the back. Then used additional wood pieces to create a bracket, using glue and brad nails to keep everything secure.

And here it is, with the screen installed. As mentioned before, I had to rotate the display 180 degrees to make it work in this cabinet. Doing this on the Raspberry Pi is really easy, and here are the steps:

- Plug in a USB keyboard and power on the Pi

- Once EmulationStation has booted, hit F4 to launch the command console

- Type the following in the command line to edit the Configuration file:

- sudo nano /boot/config.txt

- Now add the following to the bottom of the configuration file and save:

Go ahead and reboot, and the display will show right-side up (on your upside down screen)! If you ever need to revert back, setting display_rotate to 0 or deleting the line will set everything back to normal.

Next up is the artwork and installing all of the buttons.